고객 배경:

클라이언트는 허난, 중국에서 R & D, 생산, 가공 및 판매를 통합하는 포괄적 인 기업입니다. 설립 이래 새로운 환경 친화적 인 난연 재료, 고무 첨가제, 고무 필러 및 신소재 개발에 전념해 왔습니다.

Challenge:

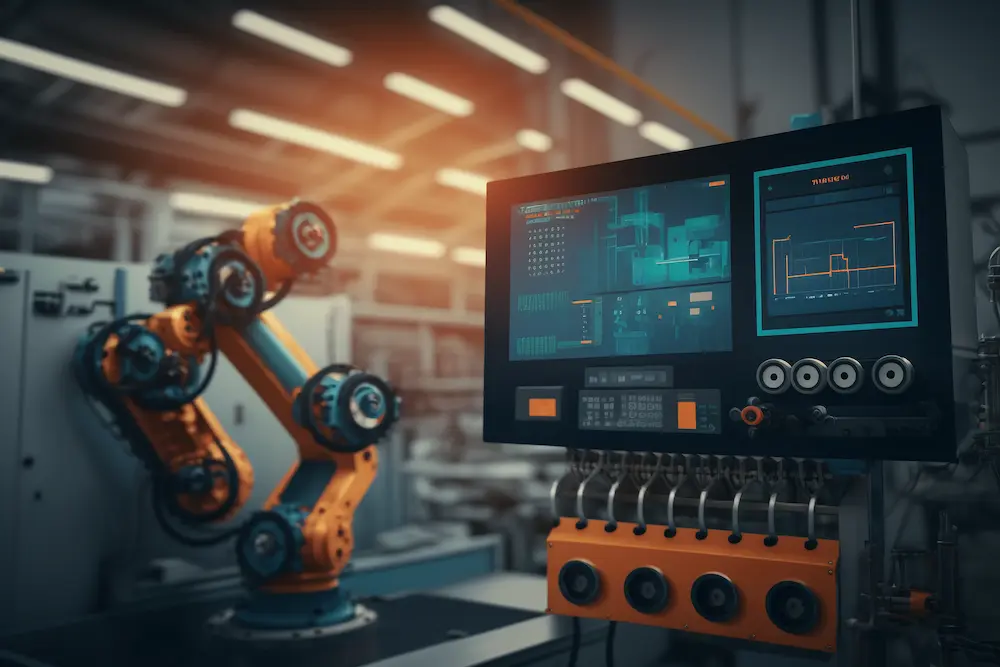

In the past, the client has always relied on worker memory and paper records for warehouse management. However, data confusion caused by human error and management inconvenience caused by the loss of paper documents has lowered the overall operational efficiency of the warehouse. To establish efficient warehouse management and improve order processing capabilities, the customer intends to adopt a complete WMS system coordinated with computer equipment to automate the warehouse operating process. Still, the warehouse's poor use environment makes it difficult for the customer to choose suitable equipment.

Solution:

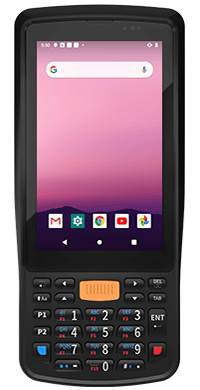

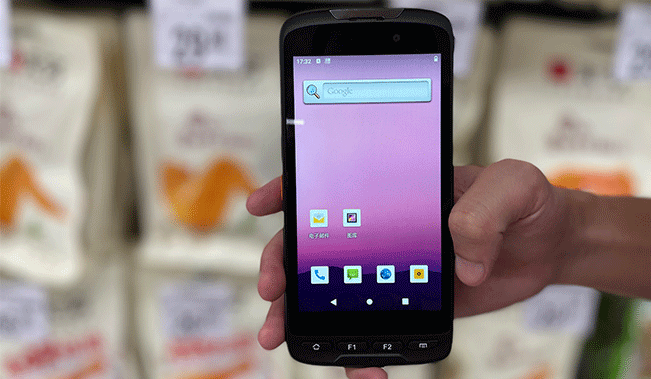

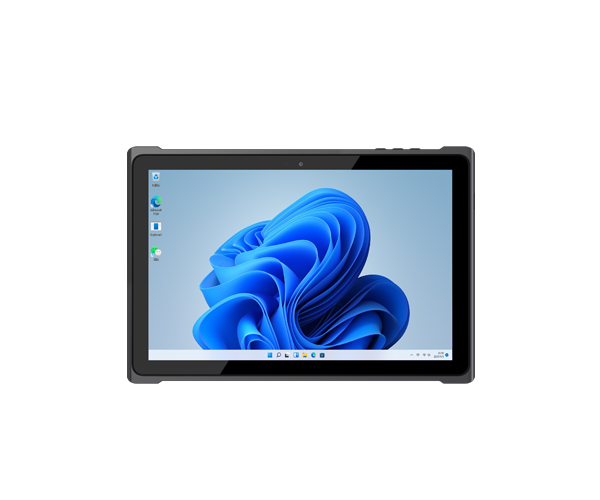

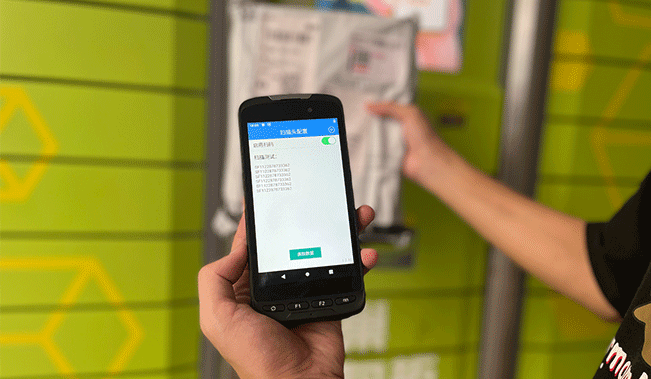

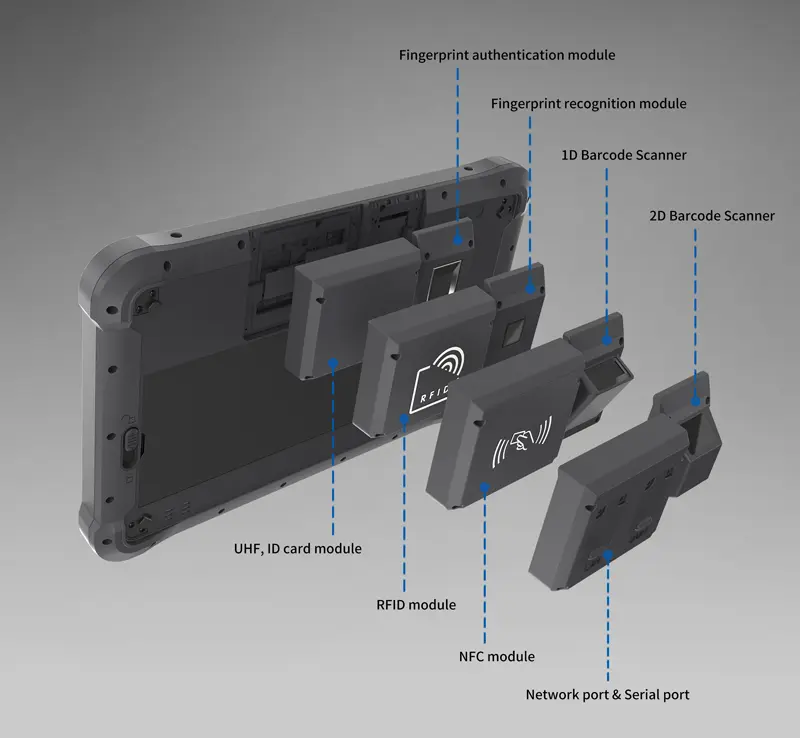

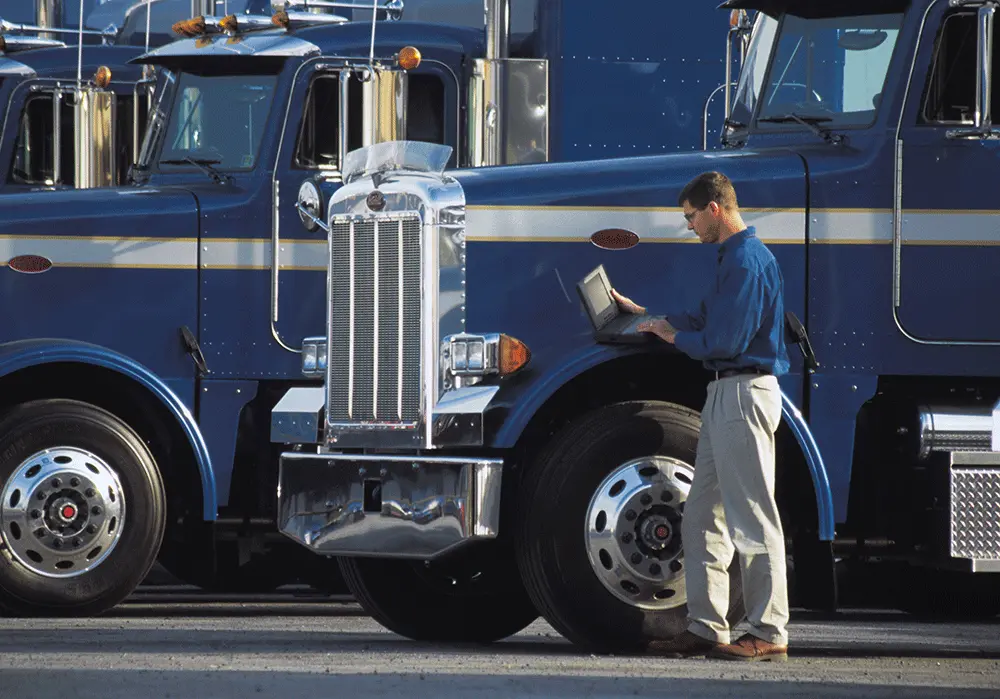

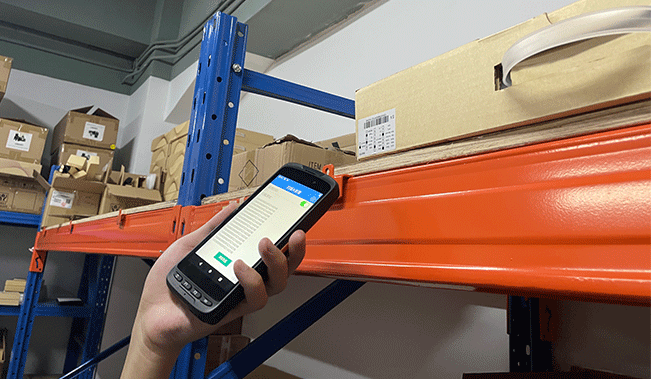

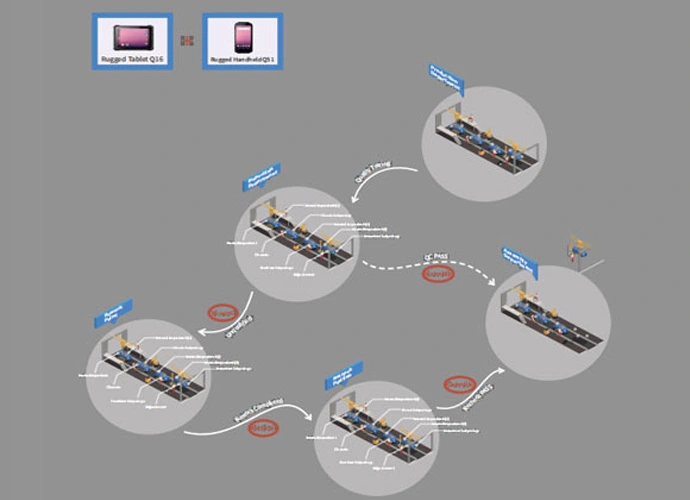

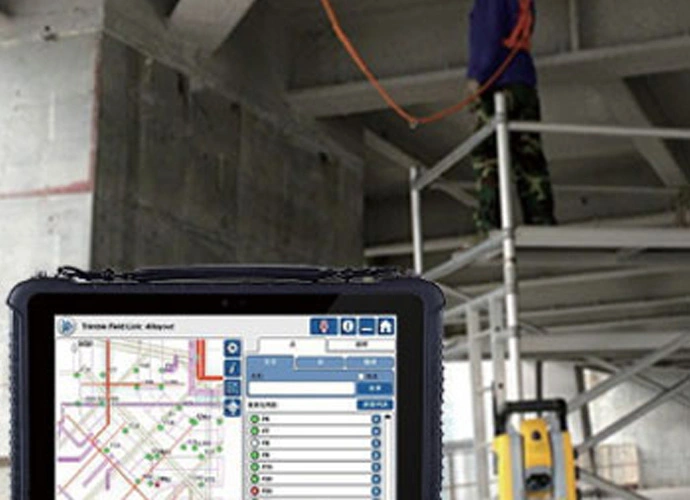

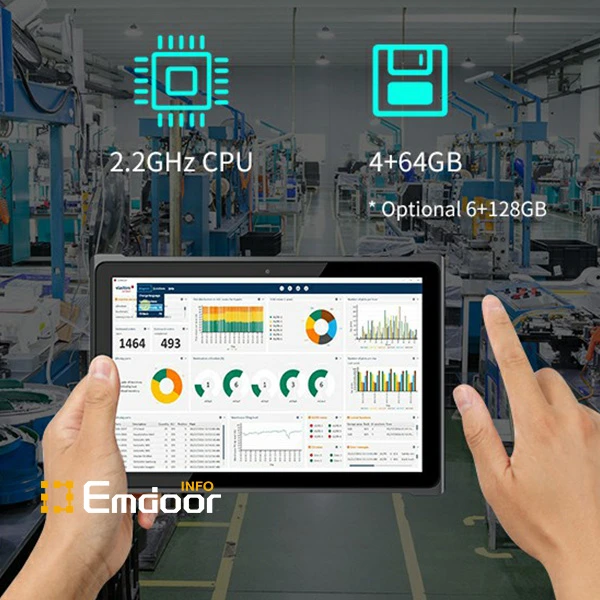

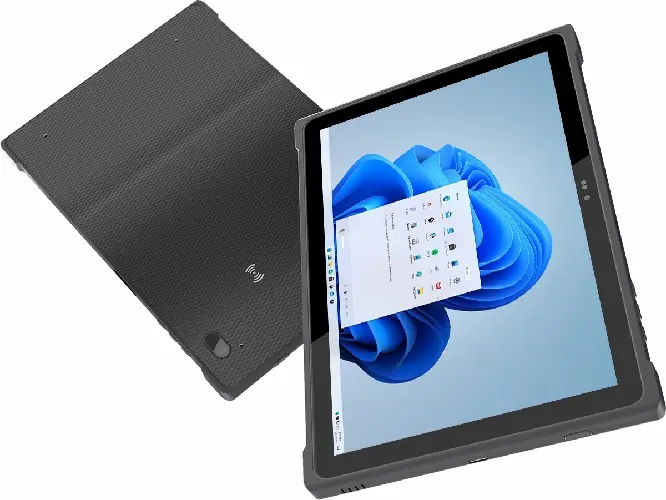

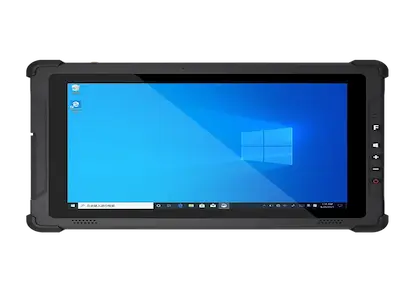

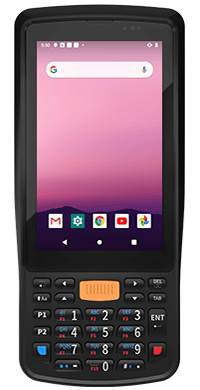

With the seamless collaboration between Emdoor's rugged tablet EM-I86H and the WMS system, customer enterprises can automatically collect information on incoming and outgoing goods, eliminating manual input errors and accelerating the warehouse's efficient and lean operation. And tablet with barcode scanner can upload real-time data wirelessly to ensure that all data-related warehouse management details are quickly and accurately organized, avoiding repetitive and unnecessary work.

Benefits:

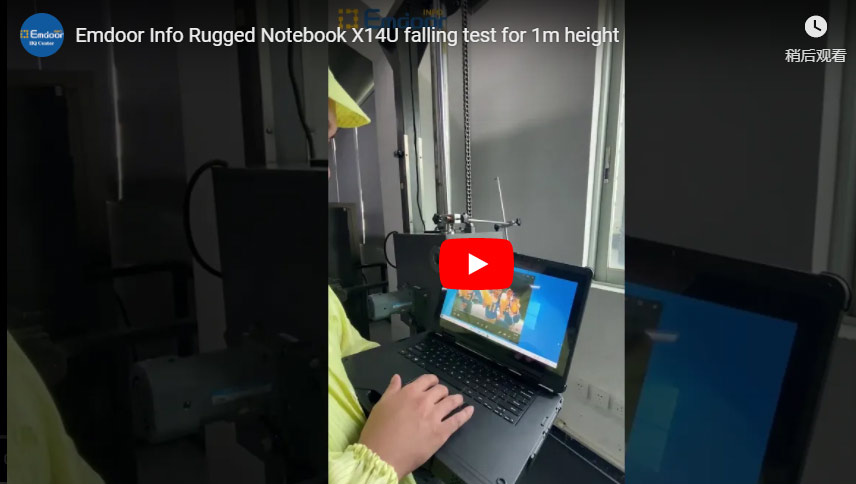

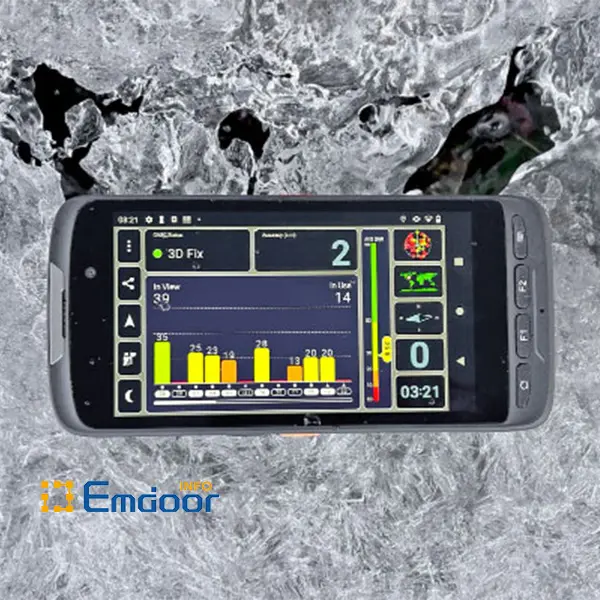

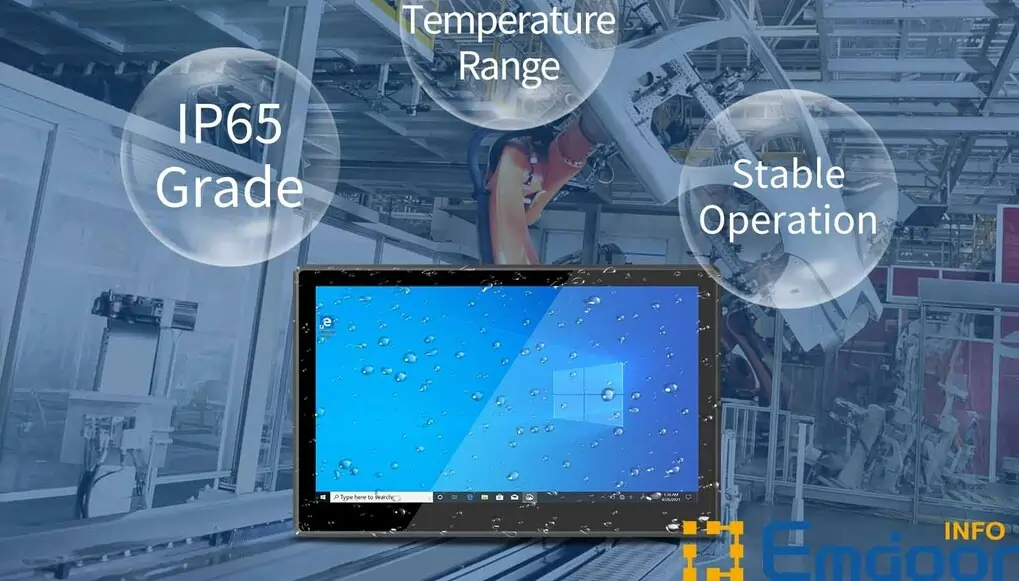

Computer equipment operating in warehouses is subject to drops, dust, vibration, and high and low temperatures. Rugged tablet with barcode scanner like the Emdoor EM-I86H, which passed MIL-STD-810G, and IP65 tests, can fully handle any issues that may arise in a factory environment and provide workers with reliability for everyday use. Even with many obstacles in the warehouse, the EM-I86H's powerful wireless connection still enables real-time communication speeds with the WMS software, which is critical to improving the operation of the entire warehouse process.

Challenge:

Under the pressure of increasingly fierce market competition, the customer company realizes it is imminent to establish a centralized information management system to fully grasp the data in all aspects of daily warehouse operations and accelerate process automation from goods inbound to outbound. But for many years, the only way for the client company to enter critical data information was through manual recording and circulation of paper documents. This cumbersome and error-prone process reduces the ability to coordinate inventory, process orders, and deliver a highly responsive customer service experience. Thus, the client determined to deploy a warehouse management system (WMS) and computer equipment to the warehouse.

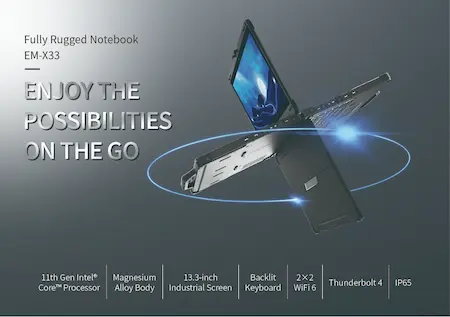

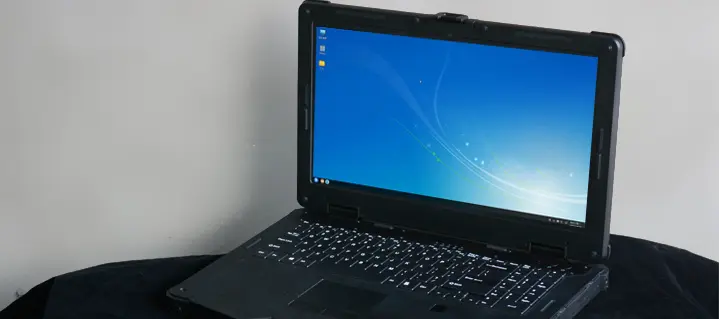

When considering equipment, the customer first thinks of ordinary consumer computers with familiarity. But unfortunately, consumer computers aren't durable enough to withstand the harsh industrial environments —long-term computing tasks under conditions whose unsuitability may cause maintenance costs to increase over time.

Only a rugged tablet with excellent durability, shock resistance, wireless communication capabilities, and long battery life is the best choice to assist warehouse personnel in running their business efficiently.

Solution:

After several rigorous tests on multiple ruggedized mobile computing devices in a warehouse environment, Emdoor's EM-I86H rugged tablet was finally proven to be the most suitable PC for customer operations management systems. It provides workers in expansive warehouse spaces with secure, continuous system access to reduce lag time for data collection and distribution without sacrificing computing power or application loading speed.

Since 52 rugged tablets EM-I86H were installed in the crane operation room of the customer's factory through the vehicle-mounted bracket to run the alumina storage scheduling operation with the WMS management system, the order processing speed of the customer's factory has also increased by 30%. Now the warehouse staff of the customer's factory can receive the latest alumina scheduling instructions online from the business & production side and upload timely data to management for review only using the EM-I86H tablet.

The systematic, digital way of working reduces the costly loss of delayed data reporting and data entry errors in the past, allowing order operators to receive orders, process goods, record data, and quickly complete orders efficiently possible. At the same time, it also allows the warehouse department to grasp the order situation in time and make reasonable resource allocations.

고객 공장의 운영자는 창고 워크 플로 데이터를 입력하거나 제한없이 생산 주문을 검색 할 수 있으며 창고 관리는 EM-I86H 견고한 태블릿 덕분에 현재 재고 수준을 추적 할 수 있습니다.

EM-I86H 태블릿은 WIFI 무선 통신 네트워크를 통해 언제 어디서나 창고 운영자에게 안정적인 연결 기능을 제공합니다. 이를 통해 운영자는 WMS 시스템에 즉시 액세스하여 주문 상태 및 창고 관리의 모든 데이터 정보를 원격으로 업데이트 할 수 있습니다. 전자 데이터 교환을 사용하여 손으로 쓴 선택 목록 및 재고 업데이트 양식의 이전 표준 프로세스를 대체하여 높은 투명성으로 인적 오류 가능성을 줄입니다.

견고한 태블릿 EM-I86H 인해 주문 배치 및 창고 관리는 더 이상 예전만큼 번거롭지 않습니다. 생산 및 상업 부서는 인바운드 및 아웃 바운드 수요를 직접 생성하고 주문을 운영 부서에 전송할 수 있습니다. 또한 시스템을 통해 재고 수준 및 판매 진행 상황에 대한 최신 보고서를 신속하게 얻을 수 있습니다. EM-I86H 태블릿으로 단순화 된 프로세스는 고객의 회사가 제 시간에 고객 주문을 이행 할 수 있도록합니다.

EM-I86H 견고한 태블릿은 MIL-STD-810G 낙하 및 진동 인증을 받았으며 IP65 테스트를 통해 최대 1.22 미터, 빈번한 흔들림, 먼지 및 물에서 살아남을 수 있습니다. 견고성은 정기적으로 장비를 유지하는 데 소요되는 시간을 줄여 직원들이 작업에 집중할 수 있도록합니다.

Emdoor Rugged PC에 관심을 가져 주셔서 감사합니다!

양식을 작성하여 귀하의 필요를 알려주십시오. 최대한 빨리 연락 드리겠습니다.