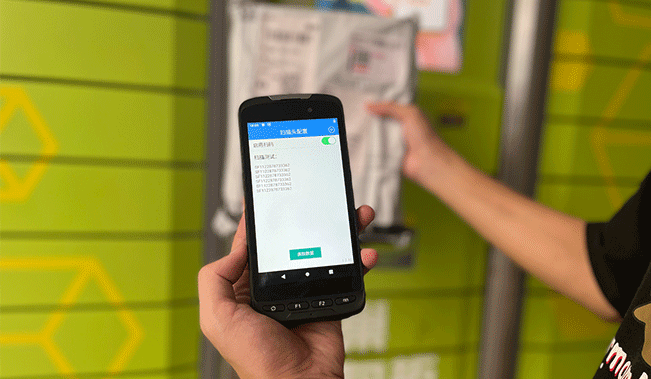

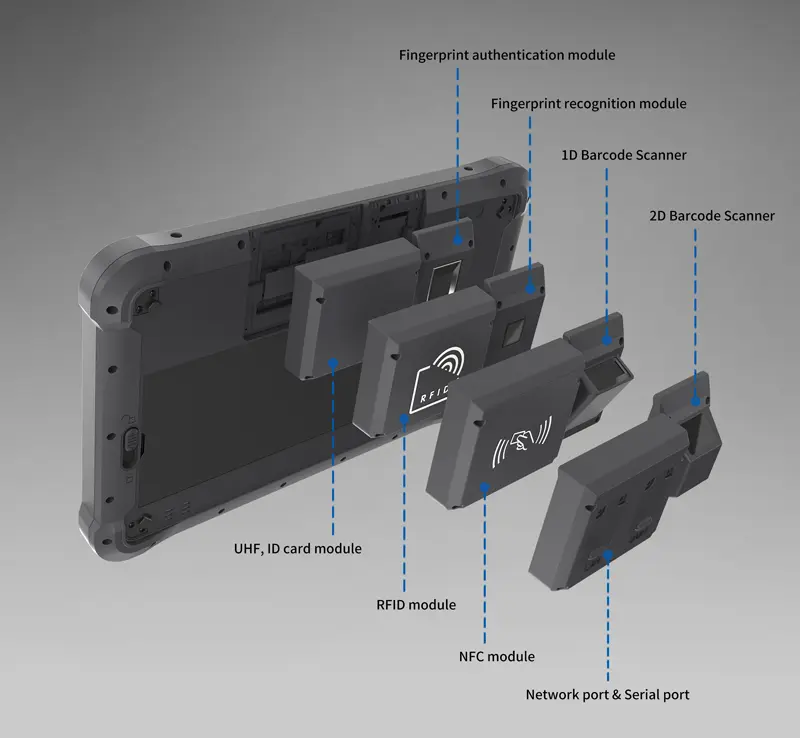

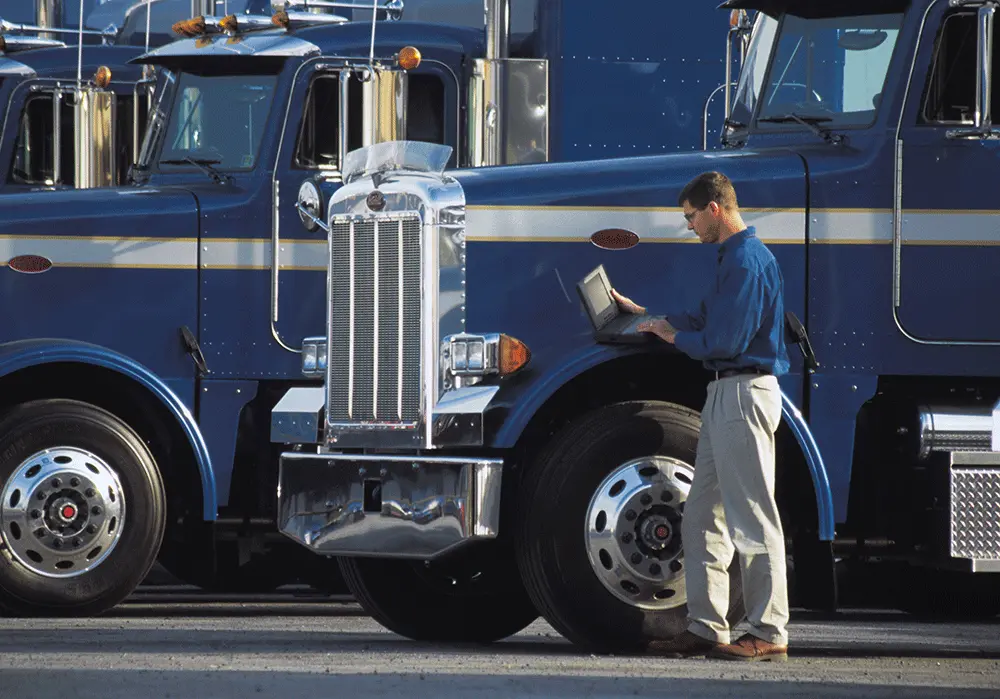

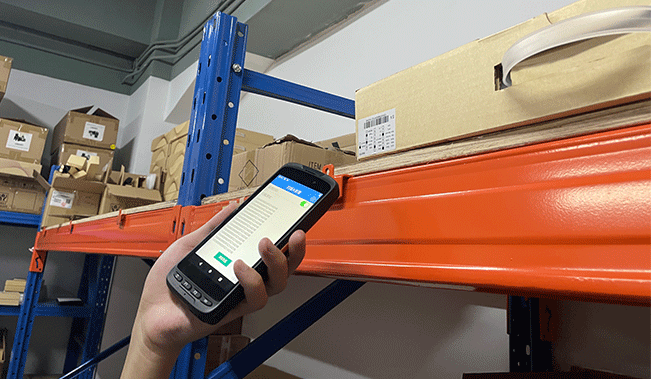

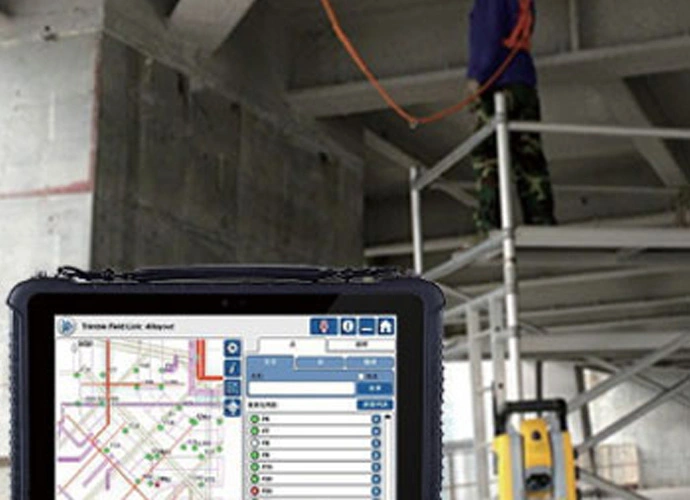

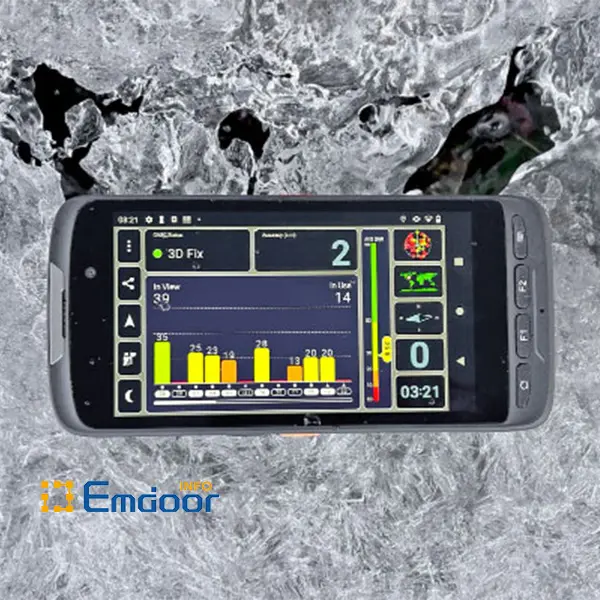

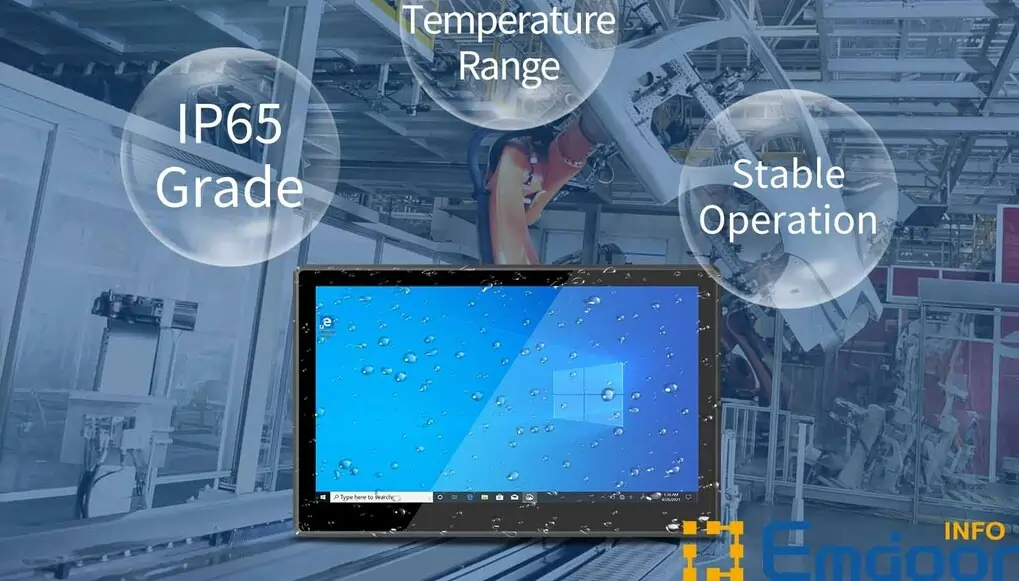

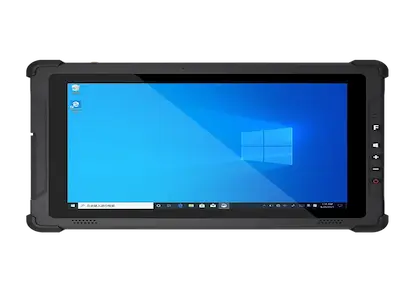

The touch screen industrial tablet pc has the characteristics of dustproof, waterproof, anti-interference, etc., suitable for use in industry, and can adapt to the harsher industrial environment. Another feature of the rugged tablet PC can establish its position in the field of industrial products, that is, the touch screen design.

At present, most of the ruggedized touch screen industrial tablet pc on the market can already provide touch control, virtual buttons, highlight customization, and high light transmittance. They can be repeatedly touched without causing mechanical fatigue, and they have basically become the standard in the industrial touch screen tablet pc market.

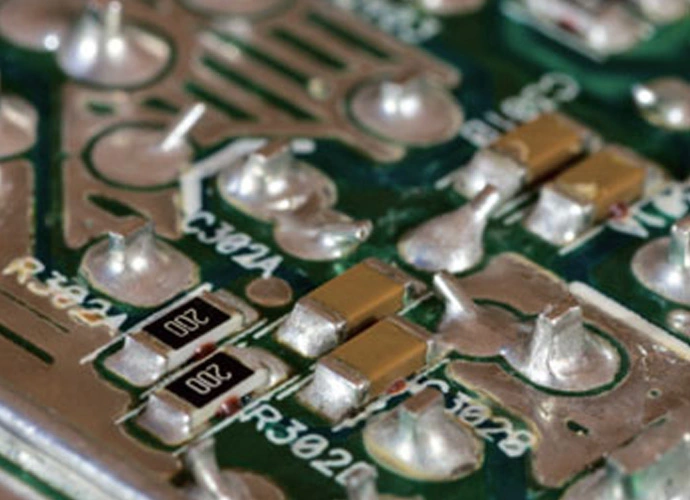

In the past, mechanical physical buttons have problems such as low operating life, water seepage easily, dust, etc., and the application principle of resistive touch ITO film is as prone to fatigue problems as mechanical buttons. The new capacitive type is used, whose touch technology can greatly improve the aforementioned mechanical fatigue and malfunction. For the rugged tablet PC, resistive touch and capacitive touch are the two main touch methods.

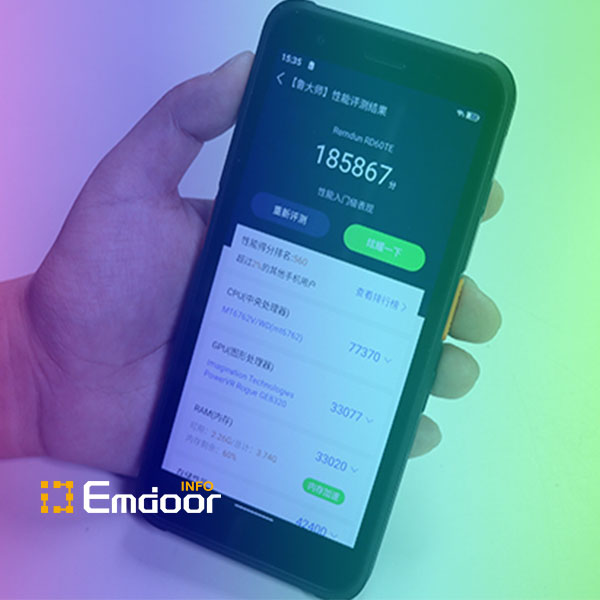

Resistive touch mode transforms the touchpoint coordinate based on the physical position of the touchpoint. 4, 5, 7, and 8-wire touch screen designs are so common. However, resistive touch screens have many physical limitations, from the short service life (the life of a 4-wire resistive touch screen can last about 1 million touches) to ITO with a certain degree of transparency which actually affects the quality of the picture.

Capacitive touch has a penetration rate of up to 97%, making the screen output effect closer to the real color. And its service life is longer, which can withstand up to 200 million touches.

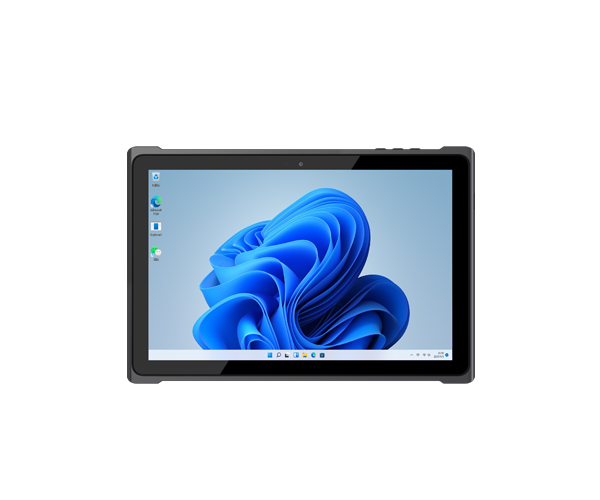

Common rugged design tablets often require the thickness of the cover layer to be less than 3mm. This is because a too-thick cover layer will cause the capacitance difference of the touch response to be below, which will degrade the quality of the contact detection signal. However, as more and more rugged design tablets support large screens and the need for multi-touch detection emerges, the development resources of rugged tablet PCs must focus on introducing high-level technical solutions for improvement. And the technologies are mainly used in the industrial rugged tablet.

Five-wire resistive screen: on the base layer of the five-wire resistive technology touch screen, the voltage fields in both directions are applied to the conductive working surface of the glass through a precision resistance network. Simply speaking, the voltage field in two directions is time-sharing work. On the same working surface, the outer nickel-gold conductive layer is only used as a pure conductor, and the position of the touchpoint is measured by the method of time-sharing detection of the X-axis and Y-axis voltage values of the inner ITO contact point after touching. The five-wire resistive touch screen requires four leads on the inner layer of ITO and only one conductor on the outer layer. There are 5 lead wires for the touch screen.

Features: High resolution and high-speed transmission response. The surface hardness is high for reducing scratches and bruises and for anti-chemical treatment. 30 million times of touching at the same point can still be used. Conductive glass is the substrate medium. One-time calibration supports high stability and never drifting.

Multi-touch capacitive touch technology has gradually matured, and most of the solutions have adopted SoC technology integration, and the difficulty of introduction is relatively low.

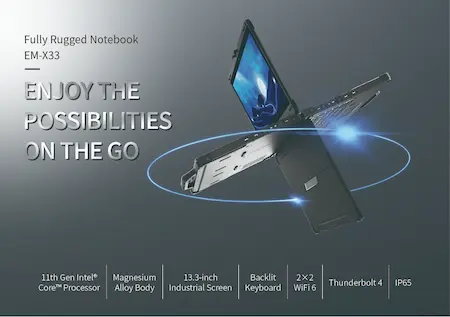

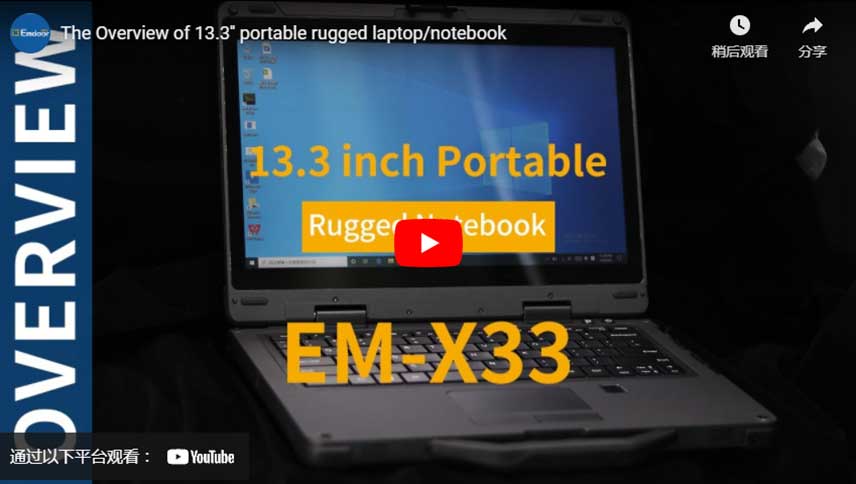

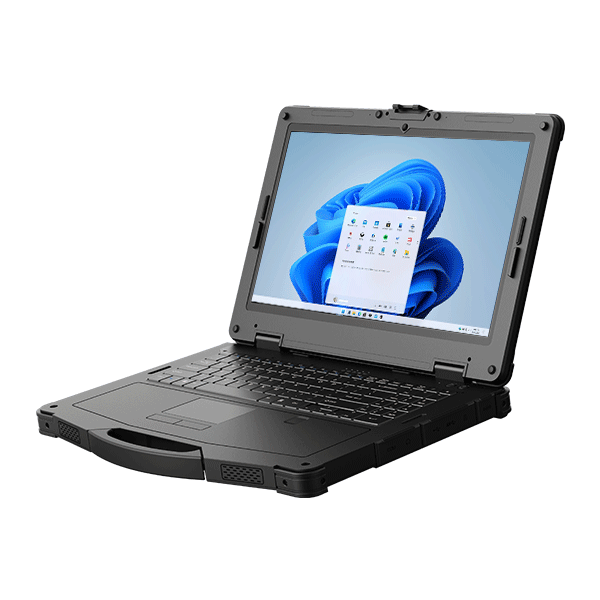

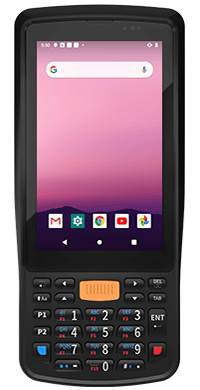

As one of leading rugged tablet manufacturers, Emdoor can offer:

Restaurant order taking tablet

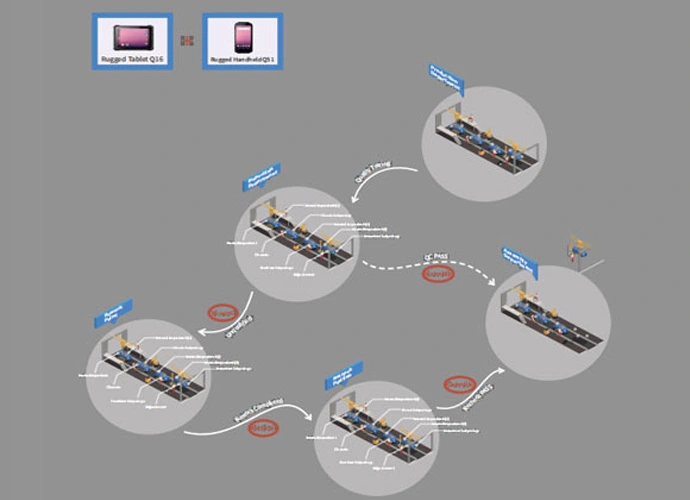

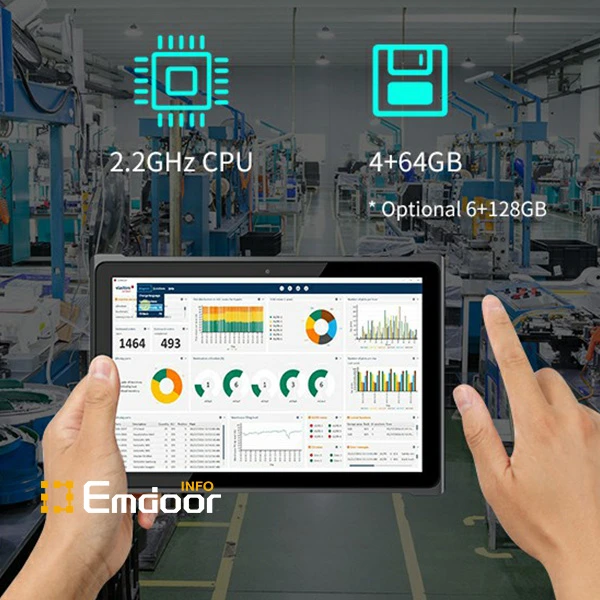

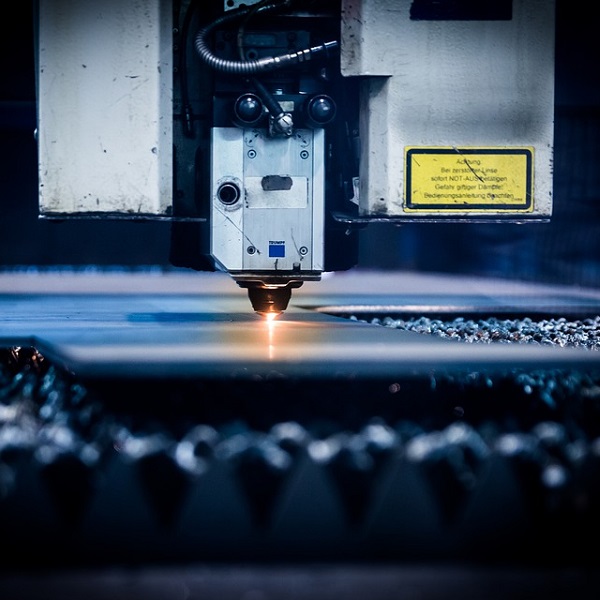

Industrial tablets for manufacturing

Click for more information.

Emdoor Rugged PC에 관심을 가져 주셔서 감사합니다!

양식을 작성하여 귀하의 필요를 알려주십시오. 최대한 빨리 연락 드리겠습니다.