배경:

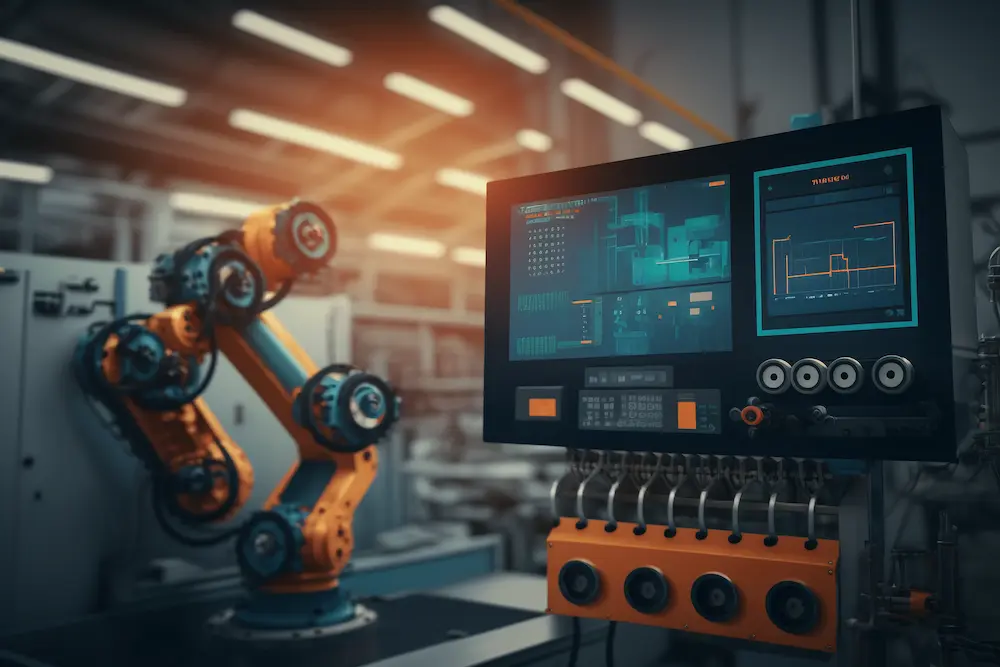

선박의 회전 장비의 전통적인 유지 보수 계획은 선박이 5 년에 한 번 또는 경우에 따라 한 달 이상 더 자주 운항을 중단하고 포괄적 인 장비 해체 검사를 수행해야합니다. 긴 유지 보수 기간은 선박의 작동 효율을 감소시킵니다. 따라서 선박 검사를 단순화하고 유지 보수 창을 단축 할 수있는 진동 분석과 같은 비파괴 기술로 상태 모니터링, 선주와 선박 관리 회사가 산업 경쟁력을 유지하는 데 도움이되는 최상의 솔루션이되었습니다.

Challenge:

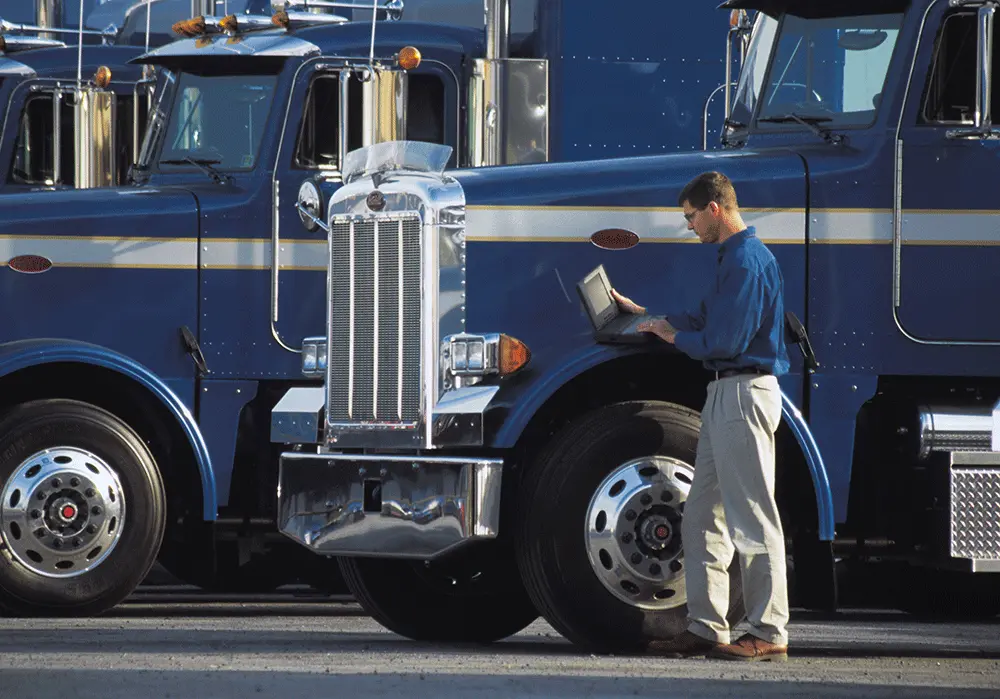

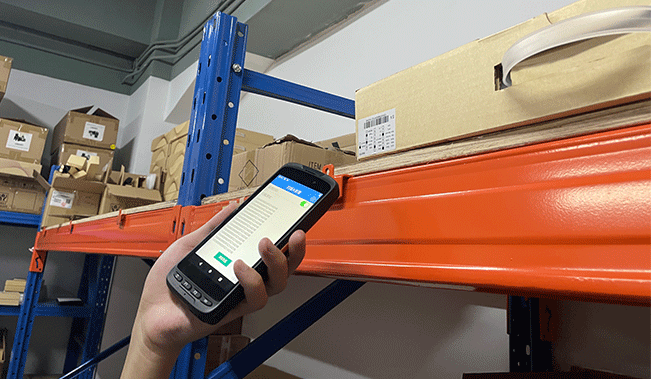

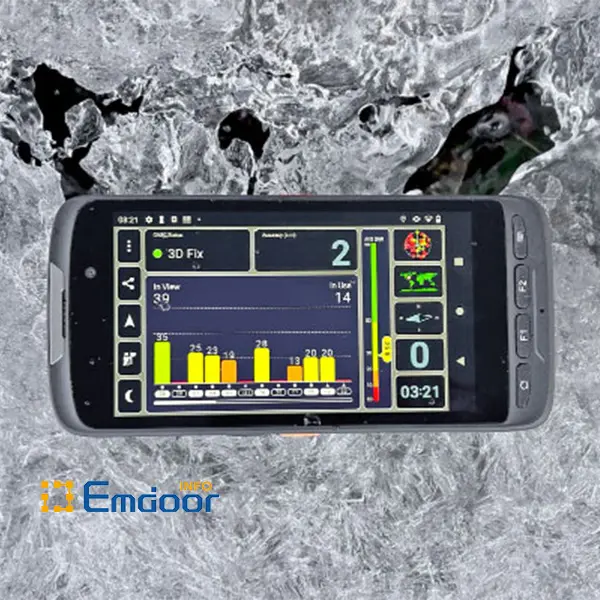

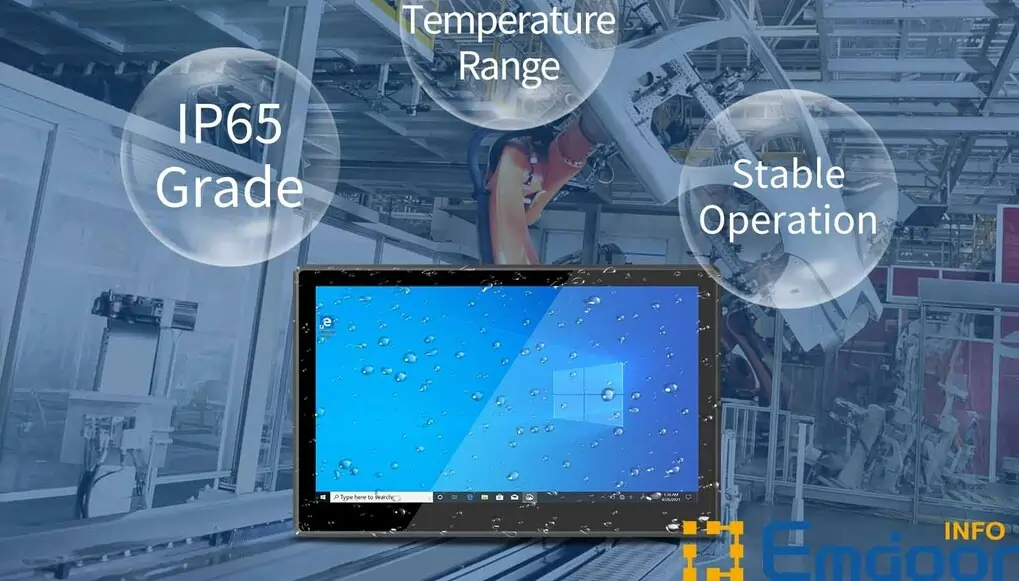

The marine environment is humid and in several geographical locations very warm, and the air is highly corrosive due to salt. Computer equipment for non-destructive testing such as vibration analysis should withstand salt spray corrosion, water mist, and the huge temperature difference between indoors and outdoors to perform daily tasks flawlessly. Furthermore, it also has to cope with the physical shock caused by a ship moving, which cannot be achieved by ordinary computers.

Solution:

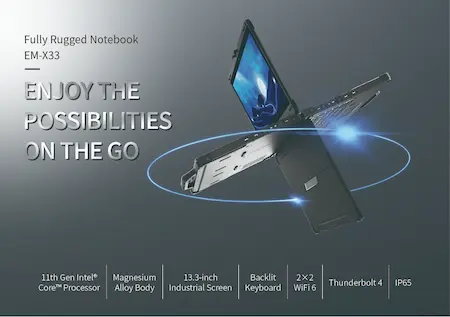

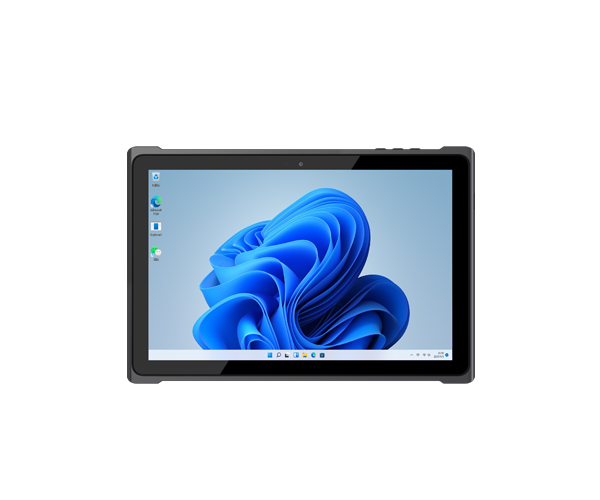

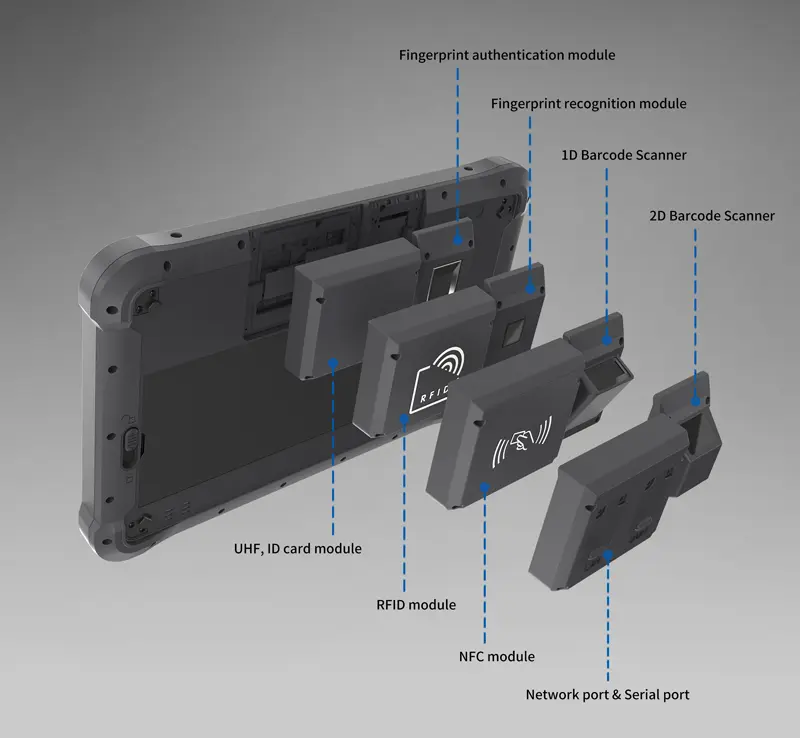

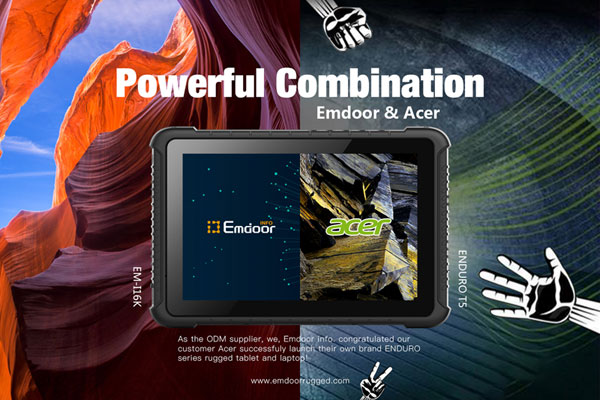

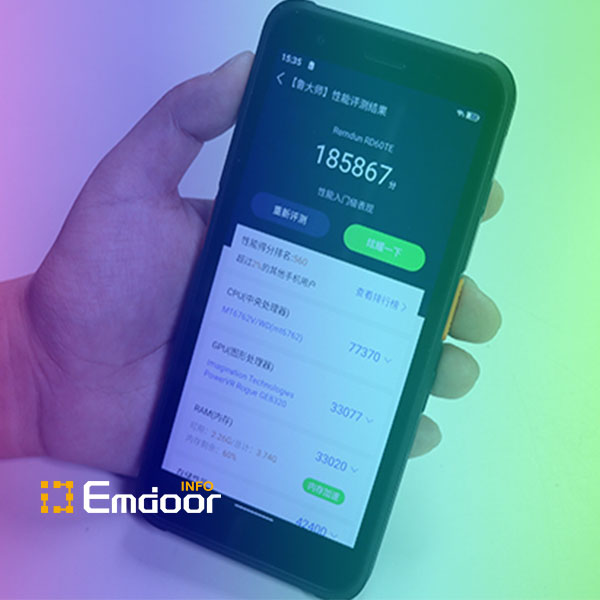

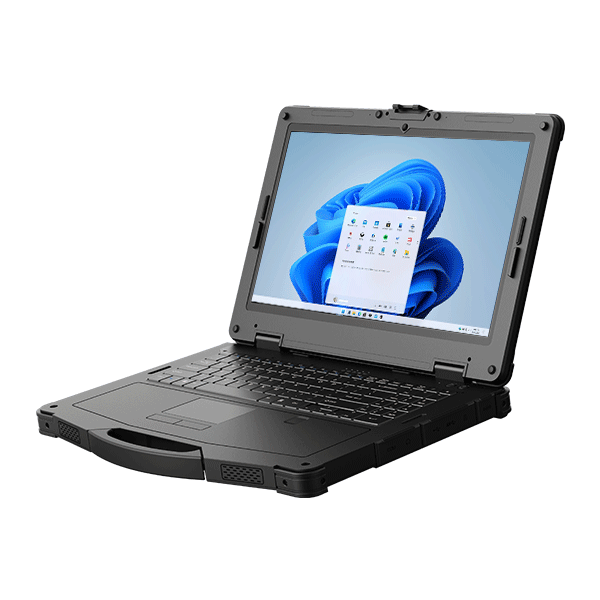

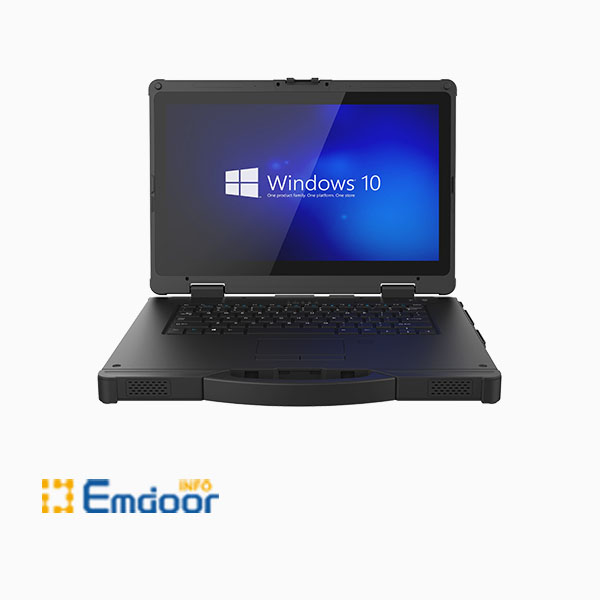

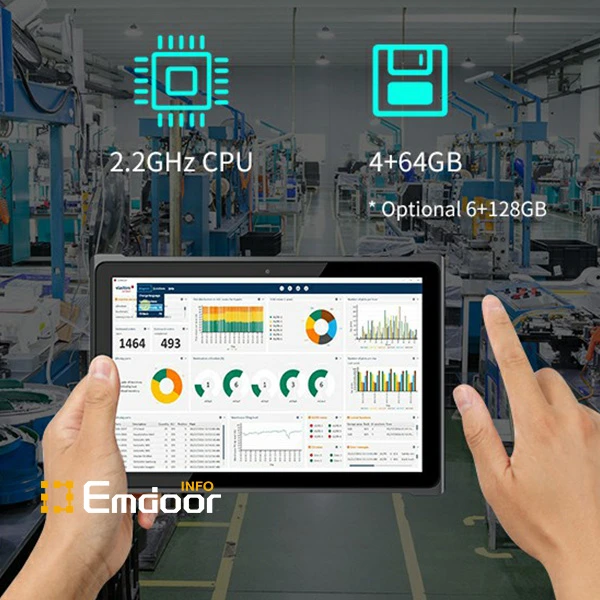

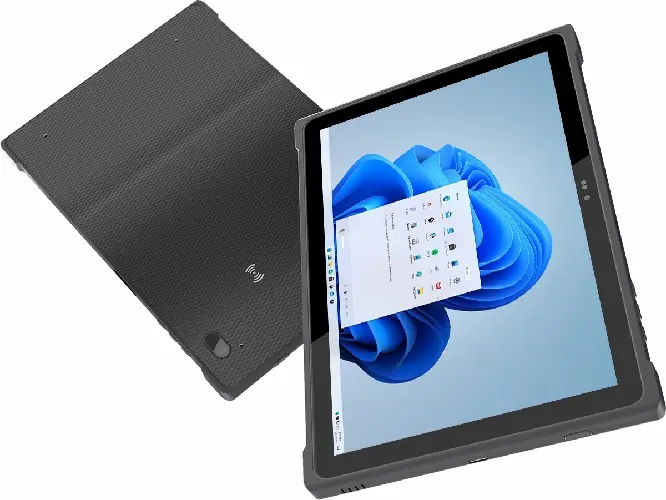

The Emdoor EM-I10J 10-inch rugged tablet windows 10 provides the most cost-effective option for efficient ship inspection, as it has a fully rugged shell, and is salt spray tested, certified to U.S. Military-810G and IP65-rated for water and dust resistance. It’s easy to use in offshore environments where corrosive electronics exist. Another key factor in choosing the I10J tablet is that it has a high-performance Intel quad-core processor that is perfectly compatible with the HAT Analytics 2nd generation digital health monitoring system Ad|Vi|Se, guaranteeing stable diagnostics.

Benefits:

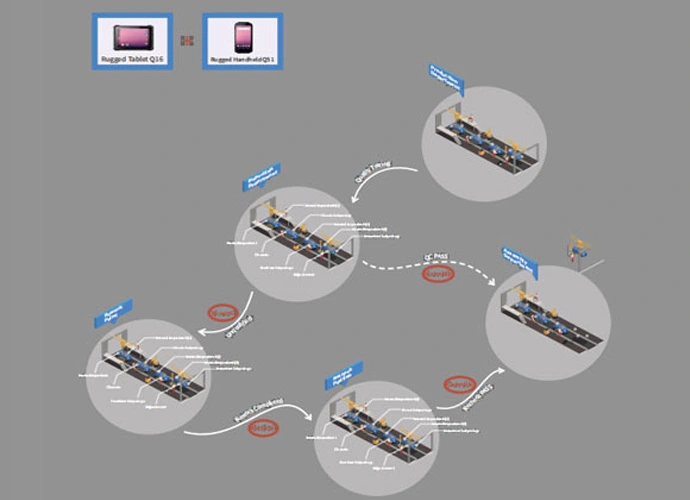

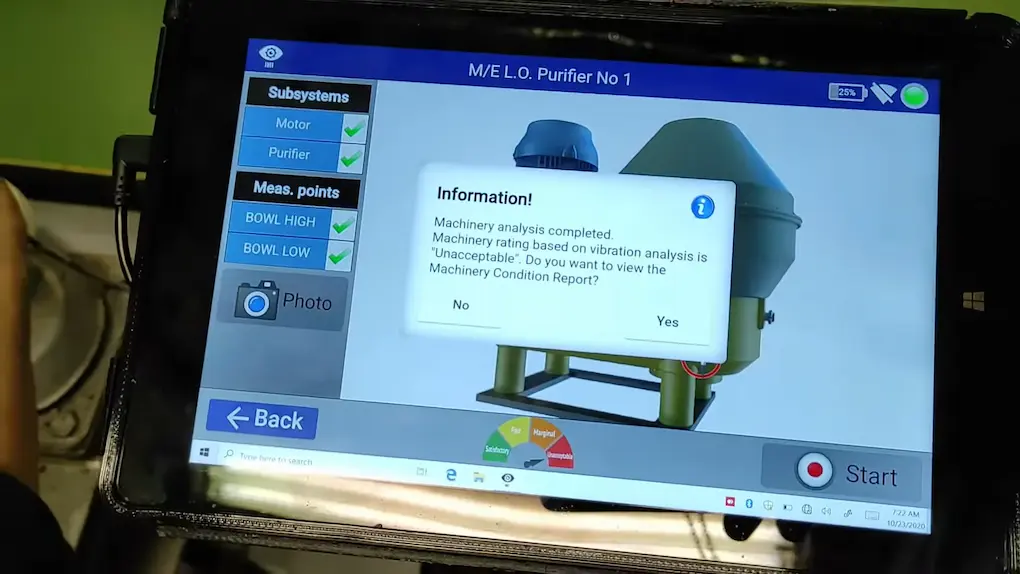

Compared with the traditional maintenance methods, the intelligent ship condition monitoring solution brought by the cooperation of the I10J tablet and the HAT Analytics digital health monitoring system Ad|Vi|Se provides a faster, more effective and reliable predictive ship machinery maintenance mode. Through portable data collection, instant health condition analysis and diagnostics, unplanned downtime and malfunctioning equipment issues are forewarned and repaired, preventing costly and time-consuming catastrophic failure events.

Challenge:

The normal operation of a ship depends on the availability of machinery on board, and regular maintenance is necessary to ensure that the ship is always in good condition. Traditional ship maintenance of the rotating equipment is based on regular openings onboard or in a shipyard, which requires dismantling transportation, and professional inspection. Thus, ships need to go out of business until the maintenance is completed. The workload is large and time-consuming, which increases the pressure on the shipping company. However, predictive maintenance programs can transform maintenance from reactive to proactive, preventing potential failures with early problem detection, increasing equipment lifespan and shortening maintenance windows.

HAT Analytics, a leading provider of predictive maintenance services, delivers innovative digital condition monitoring solutions that require the assistance of rugged mobile computing devices. Because operating offshore, where extreme temperatures, shock, vibration, and salty air are common, overly fragile equipment can add to the high cost of hardware replacement. What mobile computer is their best choice? To find this answer, HAT Analytics conducted an extensive search for data acquisition tablets that meet communication standards and field durability standards.

Solution:

Emdoor's EM-I10J industrial tablet is an ideal choice for HAT Analytics 2nd generation of digital health monitoring system Ad|Vi|Se. As part of the overall solution, its robustness and powerful computing power allow the digital health monitoring system to stably perform real-time monitoring and diagnosis of the ship's mechanical status.

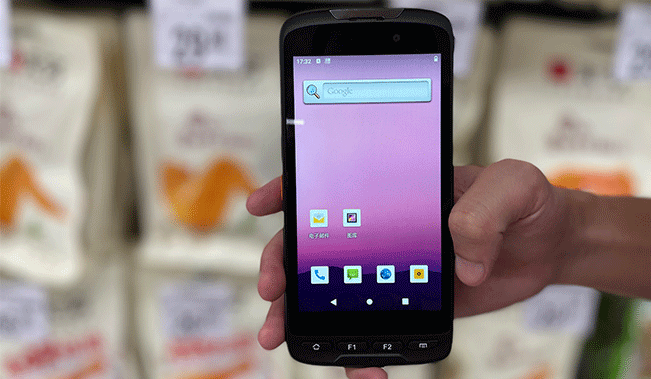

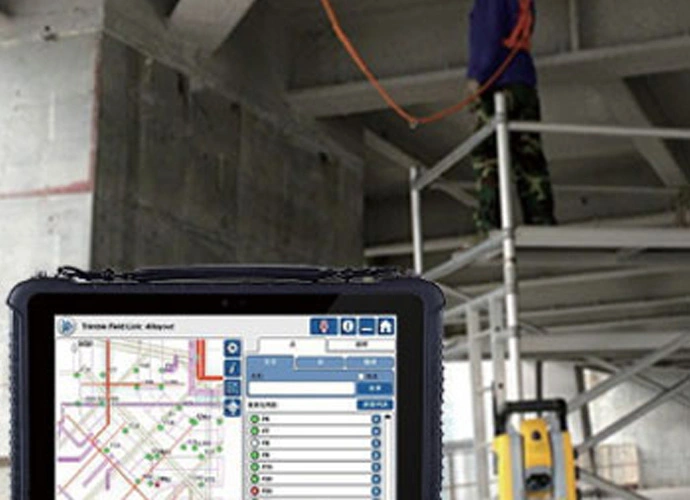

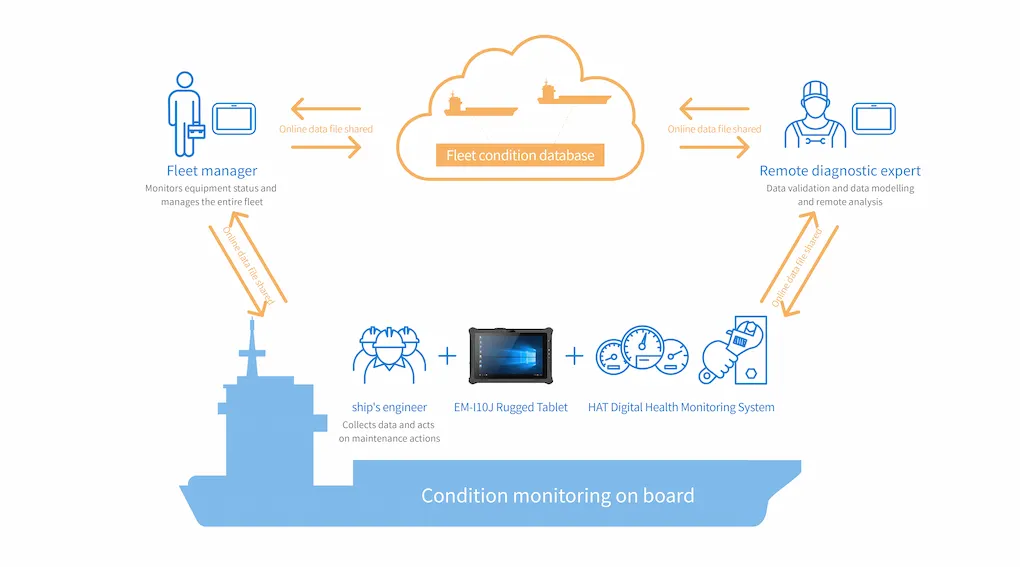

The EM-I10J industrial tablet windows, which operate in cooperation with the HAT Analytics digital health monitoring system Ad|Vi|Se, convert the collected vibration data into an easy-to-understand health report which is presented to the crew via a highly interactive user interface. With the intuitive data display, crews can get measurement results and locate the root cause of the fault faster, and maintenance can be carried out more quickly. Meanwhile, the inspection report will also be automatically generated and transmitted to the cloud server for validation and machine learning modelling through the low-latency network of the EM-I10J tablet. This increases the reliability of the health monitoring system and through the AdViSe CM Dashboard the ship's superintendent and fleet manager can securely access the information and several condition monitoring metrics of the fleet from anywhere. In the face of difficult mechanical problems, the staff can take pictures of abnormal equipment through the EM-I10J high-definition rear camera, and feed them back to the cloud to seek help from remote analysis and diagnosis by the HAT team of experienced engineers.

EM-I10J 견고한 태블릿은 광고에 대한 모든 HAT Analytics 기대치를 충족합니다. Vi | Se 장치 성능 및 내구성으로 기술자에게 다양한 상황에서 검사, 디버깅 및 문제 해결에 필요한 안정적인 플랫폼을 제공합니다. 작업 유지 보수 작업을 더 진행할 수 있습니다.

소금 노출과 관련된 해양 환경은 컴퓨팅 장비에 큰 도전입니다. 엠도어 EM-I10J견고한 태블릿 창독특한 부식 방지 기술을 제공하며, 밀봉 된 포트 디자인은 장기간 엄격한 소금 스프레이 테스트 과정에서 시스템에 소금 스프레이 손상을 방지 할 수 있으며, 컴퓨터 오류 및 작업 중단으로 인한 추가 비용 절감.

이 EM-I10J 섭씨-20 도에서 60 도의 광범위한 온도에서 작업 할 수 있으며 이는 해양 기술자에게도 중요합니다. 그들은 종종 바다, 직사광선 및 기타 가혹한 기상 조건에서 극심한 더위에서 일해야하기 때문에, 보조 도구로서의 I10J 는 신뢰할 수있는 현장 서비스를 제공하기 위해 가혹한 작업 조건에 직면해야합니다.

EM-I10J 장점견고한 창문 태블릿HAT Analytics 2 세대 시스템에 제공되는 것은 내구성뿐만 아니라 안정적인 네트워크 연결에도 있습니다. EM-I10J 고품질 네트워크 전송은 현장 기술자가 진단 데이터에 액세스하고 원격 진단 결정을 내리는 데 걸리는 시간을 단축시켜 더 높은 수준의 현장 효율성으로 작업 할 수 있도록합니다.

Emdoor Rugged PC에 관심을 가져 주셔서 감사합니다!

양식을 작성하여 귀하의 필요를 알려주십시오. 최대한 빨리 연락 드리겠습니다.